Bottled Water Production with

Alkaline Mineralizer System

Coke_bottle water |  Purewater tank |  Sila_quality control |

|---|---|---|

Blue Water Jugs |

The Market For Bottled Water Is Expanding & Evolving

The global demand for bottled water is not only growing but also shifting towards higher quality standards. Consumers are no longer satisfied with just "clean" water; they now seek better-tasting, alkaline, and mineral-rich water for a healthier lifestyle.

ROTEK has been a leading provider of water treatment systems for the bottled water industry for over 20 years. While we continue to provide industry-leading purification, we have evolved to meet the new market trend: Functional Drinking Water. Unlike competitors who focus on packaging machinery, we specialize solely in water treatment technology, ensuring every drop meets the highest sensory and health standards.

Beyond Purification: The Secret of the Taste

To help our clients capture the premium water market, ROTEK has developed the Sila Alkaline Mineralizer System. This system is specifically designed to transform RO permeate into high-quality alkaline mineral water, providing:

-

Optimal pH Balance: Natural alkalinity for a smoother, crisper taste.

-

Essential Mineral Reintroduction: Precision dosing of calcium, magnesium, and other trace minerals.

-

Superior Taste Profile: Tailored for premium bottled water brands and high-end water refill stations.

ROTEK uses a variety of technologies for clients (depending on raw water quality), which may include :

-

Reverse Osmosis (RO): Featuring our latest BWFR-HR Series for maximum purity.

-

Ultra-filtration (UF) and Nano-filtration (NF): For selective mineral retention.

-

Media Filtration & Water Softening: Customized for diverse raw water sources.

-

Sila Alkaline & Remineralization Systems: For premium mineral water production.

-

Ozone & UV Sanitation: Ensuring biological safety without chemical residues.

The Secret of the Taste:

SILA Alkaline Mineral Media

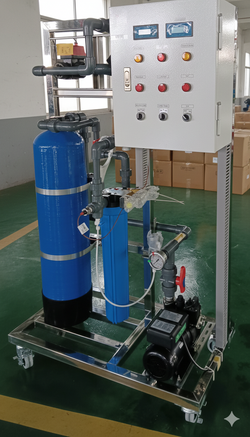

The Control of the Quality:

SILA Alkaline Water System

About Drinking Water Quality & Experience

In the modern bottled water industry, water quality is measured by both purity and palatability. To design the perfect system for your brand, a comprehensive Raw Water Quality Analysis is essential. This allows us to balance the purification process with the right mineralization strategy.

Our Commitment to Excellence:

-

Total Contaminant Removal: Ensuring source water is100% free from pollutants.

-

Advanced Mineralization: Implementing the Sila System to create a distinct and refreshing taste profile.

-

Consistency & Safety: Regularly testing water quality to meet both health regulations and brand flavor consistency.

The drinking of distilled water has been both advocated and discouraged for health reasons. The lack of naturally occurring minerals in distilled water has raised some concerns. The Journal of General Internal Medicine[16] published a study on the mineral contents of different waters available in the US. The study concluded:

Drinking water sources available to North Americans may contain high levels of Ca2+, Mg2+, and SiO and may provide clinically important portions of the recommended dietary intake of these minerals. Physicians should encourage patients to check the mineral content of their drinking water, whether tap or bottled and choose water most appropriate for their needs.